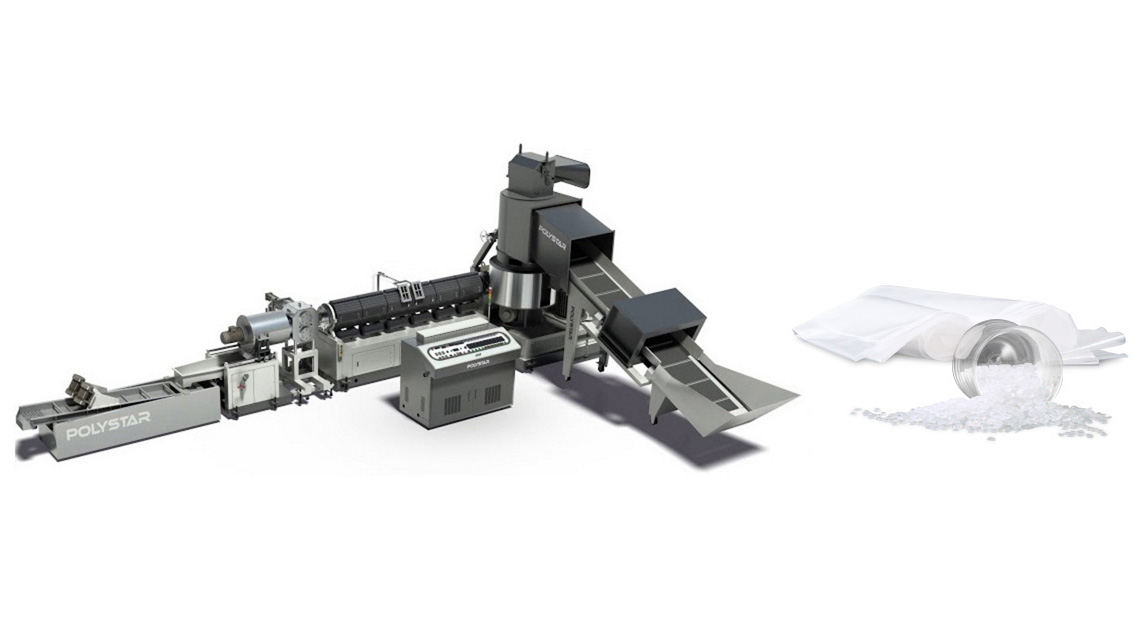

Plastic film recycling machine

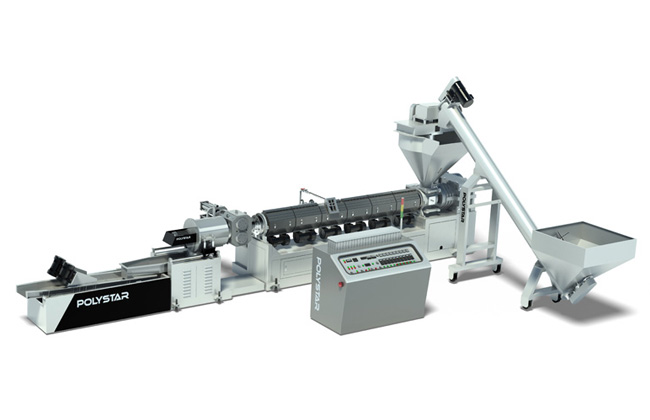

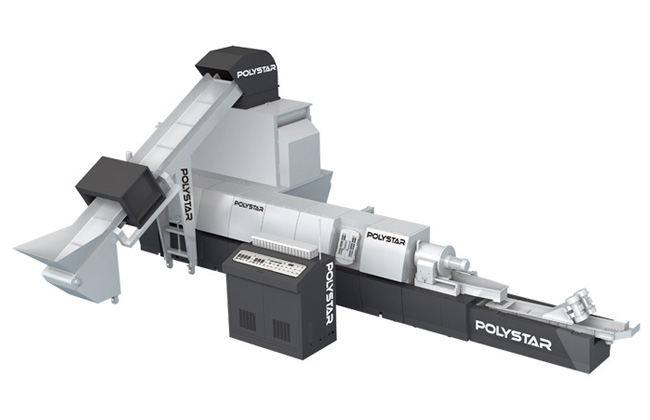

HNT-V -- High Efficiency Line for Packaging Film

About

Polystar's high efficiency, one-step plastic recycling machine HNT-V is designed for the reprocessing of PE polyethylene (HDPE, LDPE, LLDPE).Crushing

Extruding

Pelletizing

Flexible

Packaging

Material

Output

100-1200

kgs/hr

High Performance Recycling Machine

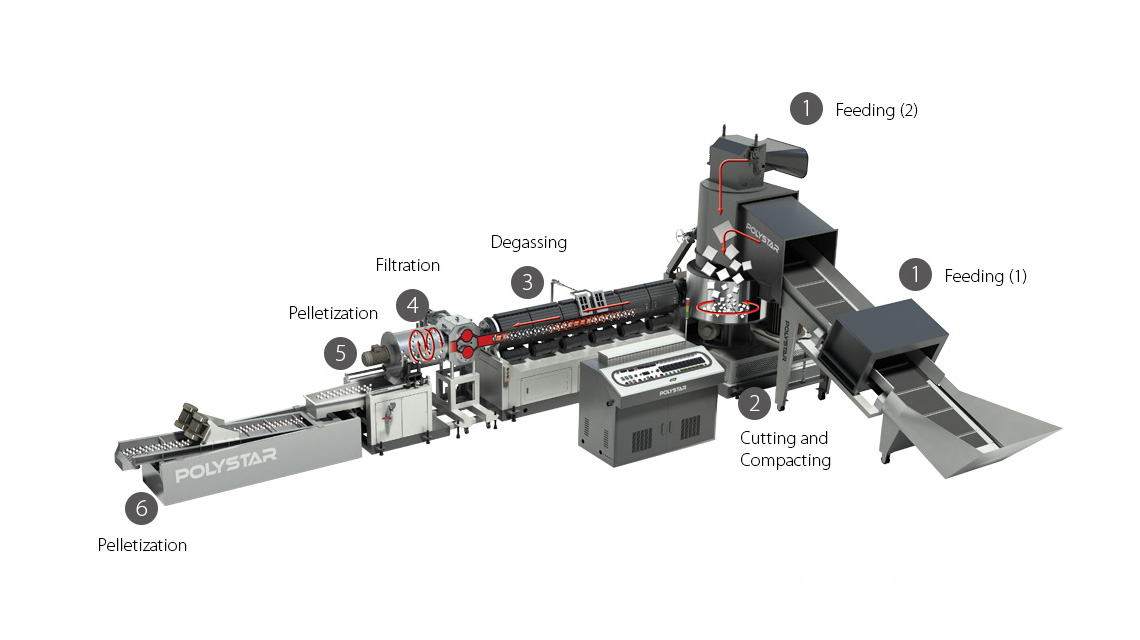

Polystar's high efficiency, one-step plastic recycling machine HNT-V is designed for the reprocessing of PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene flexible packaging material, printed and non-printed. This cutter integrated pelletizing system eliminates the need of pre-cutting the material, requires less space and energy consumption

while producing high quality plastic pellets at a productive rate. In addition to in-house (post-industrial) film waste, the system is also able to process washed flakes, scraps and regrind (pre-crushed rigid plastic waste from injection and extrusion). This equipment is highly recommended for packaging film producers of commercial bags,

garbage bags, agricultural films, food packaging, shrink and stretch films, as well as producers in the woven industry of PP woven bags, jumbo bags, tapes and yarns. Other types of material such as PS sheet, PE and PS foam, PE net, EVA, PP mixed with PU are also applicable on this machine.

Re-usable pellets

1. Pellets from in-house, post-industrial recycling

On average, post-industrial waste makes up 5% or more of the entire production line, making in-house recycling very important nowadays as it can significantly reduce the cost of raw/virgin material purchasing. The plastic pellets produced from in-house waste are almost like-new and can be re-used for producing high quality plastic products once again.2. Pellets from post-consumer recycling

The HNT-V is also designed to work with washed, post-consumer and used agricultural film. The cutter compactor, which generates frictional heat during the compacting process, helps to further dry and remove the water moisture from the washed film flakes (processed first by the washing lines). The recycled pellets can be used again in extrusion process, whether 100% (such as garbage bag, LDPE pipe production and etc) or as part of the mixture to reduce raw material cost. The pellets quality can also be improved by direct dosing of masterbatch and additives.Model Comparison

| Model | Output |

A (Standard) |

A (With all option) |

B (Standard) |

B (With all option) |

C |

|---|---|---|---|---|---|---|

| HNT-65V | 80-120 Kgs/hr | 5250 | 6000 | 7300 | 10000 | 2900 |

| HNT-85V | 180-250 kgs/hr | 5950 | 7000 | 8200 | 12000 | 3100 |

| HNT-100V | 300-400 kgs/hr | 6600 | 8000 | 9400 | 12000 | 3200 |