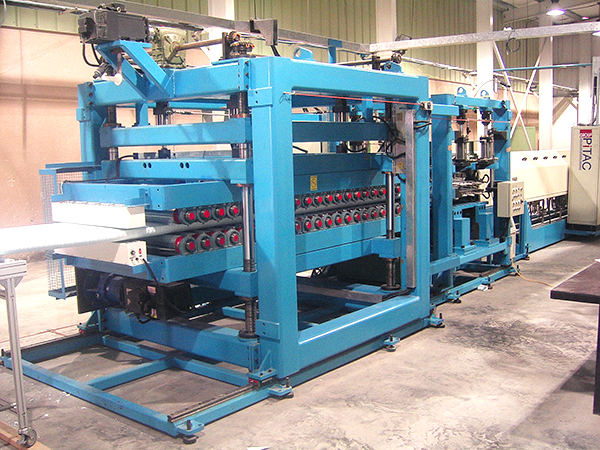

XPS Extrusion Line Features :

- With proper mixing of melted resin & blowing agent, provides most homogeneous mixing.

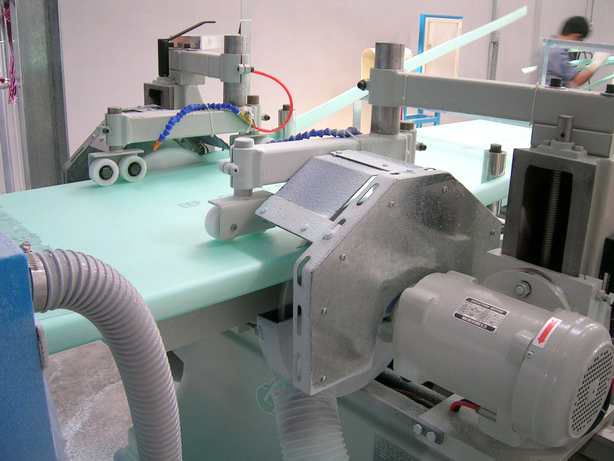

- Accurate blowing agent injecting quantity and temperature control to stabilize the foaming process.

- High level safety control, system will be shut down automatically when extruder motor failure or high pressure.

Fully alarm system to tell operator the real-time machine conditions :

PLC & WEB Based Computerizing control system recording all the operating condition & parameters, operator will be able to trace log file for quality control. AC driving system work with most updated version of Inverter to give lowest energy consumption. Remote monitoring function will let production state under administrator’s 100% control. Optima die flow channel design; generate most homogeneous & proper cell size structure. With remote troubleshooting function through internet, Pitac provides most in-time after service to customer.

-

- Model No.

- PT-250PSB

- PT-450PSB

- PT-600PSB

-

- Using Material

- General Purpose Polystyrene

- General Purpose Polystyrene

- General Purpose Polystyrene

-

- Using Blowing Agent

- HCFC/HFC/ DME/Butane

- HCFC/HFC/ DME/Butane

- HCFC/HFC/ DME/Butane/CO2

-

- Max. Output (kg/hr)

- 300

- 450

- 600

-

- XPS Sheet Min. Density (kg/M3)

- 32~35

- 32~35

- 32~35

-

- XPS Sheet Thickness (mm)

- 25~65

- 25~100

- 25~100

-

- XPS Sheet Standard Width (mm)

- 620

- 620

- 620

-

- XPS Sheet Standard Length (mm)

- 1250

- 1250

- 1250

-

- Sheet Edge Shiplap

- Optional

- Optional

- Optional

-

- Sheet Edge Tongue & Groove

- Optional

- Optional

- Optional

-

- Production Power Consumption

- 250KW

- 300KW

- 400KW

-

- Water Consumption

- Closed-loop circulation

- Closed-loop circulation

- Closed-loop circulation

-

- Machine Occupation Area

- 6M(H) x 5M(W) x 55M(L)

- 6M(H) x 5M(W) x 70M(L)

- 6M(H) x 5M(W) x 80M(L)

-

- Machine Type

- Tandem extruder

- Tandem extruder

- Tandem extruder

-

- Control System

- PLC & PC-Based

- PLC & PC-Based

- PLC & PC-Based

-

- Operating Interface

- Web Based

- Web Based

- Web Based

-

- Remote Troubleshooting

- YES

- YES

- YES

-

- Operating Log

- YES

- YES

- YES

-

- Environment Temp. Control

- Recommend

- Recommend

- Recommend

-

- Auto Material Blending System

- Optional

- Optional

- Optional

-

- Blowing Agent Synchronize System

- Optional

- Optional

- Optional

-

- Auto-Screen Changer

- Optional

- Optional

- Optional